Important information about the manufacturer and technology

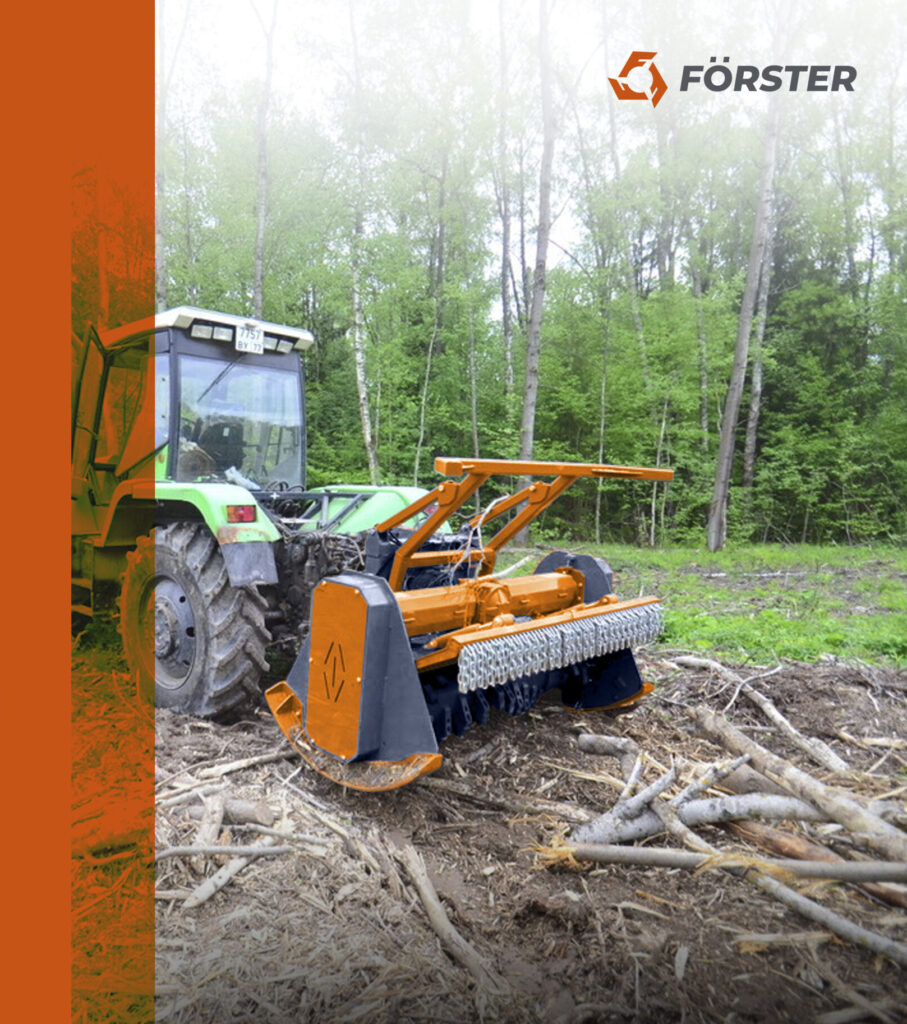

FÖRSTER FORESTRY MULCHERS

designed and manufactured in Italy

The company’s production facilities are located in the machine-building region in northern Italy.

- The production, which began in the manufacture and repair of agricultural equipment, was quickly transformed to meet the specific needs of professional clearing enterprises. This transition required not only a change in the model range, but also the introduction of advanced metalworking technologies.

- The plant is proud that over the years it has provided the best service and product quality for the most specific and demanding customers. After all, the main goal is to ensure that Forster equipment works daily regardless of environmental conditions. That’s why engineers pay special attention not only to the layout and design of products, but also to the quality of components.

- The housing is made of Hardox and Domex steels, so that forest mulchers have unsurpassed resistance to any kind of wear, and this is in balance with a moderate cost. In the continuous process of product improvement, the plant has received many patent certificates.

- The plant’s forest mulchers are used all over the world, where they have proven themselves in terms of fault tolerance and performance in all climatic zones. A distinctive feature of Forster mulchers is that it is possible to apply cutting limiters to all forest models – and they increase productivity and at the same time reduce fuel consumption.

- Verified details are the key to a perfectly working machine. For example, the labyrinth rotor bearing protection system has gaps in moving parts not exceeding 1.5-2.5 mm. The rotors are mounted on removable trunnions for maintainability, regardless of the age and location of the mulcher. FÖRSTER mulchers are productivity today and high residual value after years of service.

The model range includes forest mulchers:

- for tractors with a capacity from 50 to 300 hp,

- excavators from 2.5 to 35 tons,

- front-end media from 30 to 400 hp.

The plant has implemented the ISO 9001 quality control standard