WHY CHOOSE FÖRSTER MULCHERS?

INCREASED PRODUCTIVITY

The original design of the rotor structure made it possible to increase productivity without increasing energy consumption. Thus, Forster mulchers remain economical at a high level of performance.

SPECIAL RELIABILITY

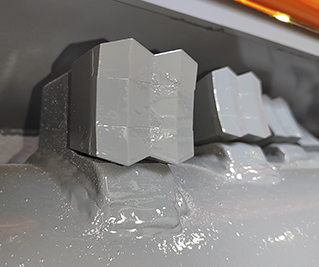

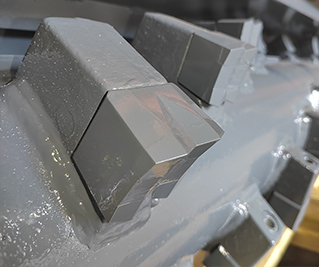

Due to the use of double-sided cutters on many models, savings can reach over euro 3,000 per year. Type B cutters have four carbide solders, and type V cutters have two sharpened cutting edges

RELIABILITY IN EVERY MODEL

The tool holders have an elongated shape for both rotors with low versions (cutters of types B, V, N) and for heavy rotors (cutters of types 2X, 3X).

OPERATOR ASSISTANCE

Compact design – increases the visibility of the work area by up to 32%, which reduces the load on the operator.

TECHNOLOGICAL SOLUTIONS THAT INCREASE DURABILITY

The rotor bearings are protected from winding by several levels – a bulging flange, and a ring encircling the rotor. In addition, due to the precise processing, the ring gap is 1.5-2.5 mm, which is almost incredible for this type of equipment

OTHER FEATURES OF MULCHERS

DURABILITY IS LAID DOWN STRUCTURALLY

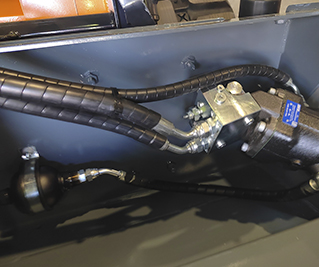

The hydraulic components of the mulchers have a multiple resource reserve. Hydraulic motors – with high torque characteristics. Each model is equipped with a Rexroth non-hull safety valve (protection against overpressure, flow and cavitation effects), as well as a Hydrosmooth system for overload protection

STRUCTURAL STEEL

The mulchers are made of Domex 600 – 700 and Hardox steels. The multi-layered housing design not only improves the deformation resistance, but the use of different types of steels provides the best protection against abrasive wear. And this applies to the entire Forster mulcher line.

MODELS FOR MINI EXCAVATORS

Förster is one of the few manufacturers that produces truly effective forest mulchers for mini excavators and other compact equipment. This was achieved thanks to an excellent understanding of the physical processes of cutting